1ケからのオーダーメイド承ります。

図面だけでなく、現物やイメージからでも製作します。

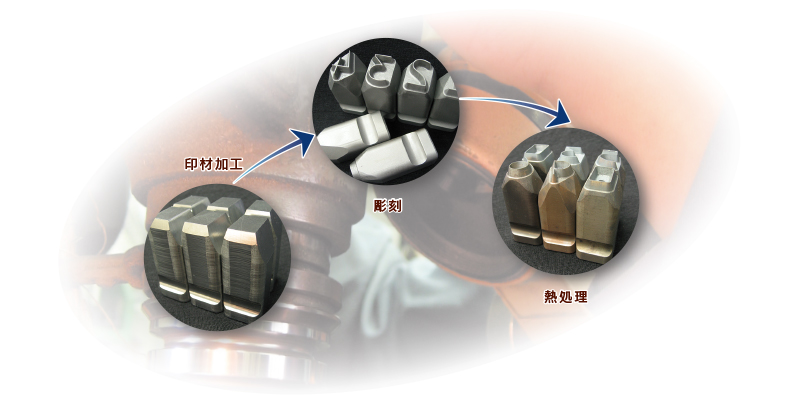

デザインから印材加工、彫刻、そして熱処理までの一貫生産にこだわり、品質管理の安定に努めています。

1.材質

主に炭素工具鋼、合金工具鋼などの鋼材を使用します。用途に合わせた材質をご指定頂けます。

| 印材用材質 | 鋼材名及び用途 | 特徴(*1) |

|---|---|---|

| S45C相当品 | 機械構造用炭素鋼 | 主に刻印間を埋めるスペーサーとして使用されています |

| SK105(SK3)相当品 | 炭素工具鋼 | コストパフォーマンスに優れ、刻印材として幅広く使用されています |

| SKS3相当品 | 合金工具鋼(冷間金型用) | 耐摩耗性に優れ、主に小~中ロット生産打刻に適しています |

| SKD11相当品 | 合金工具鋼(冷間金型用) | 耐摩耗性に非常に優れ、主に量産打刻品に適しています |

| SKD61相当品 | 合金工具鋼(熱間金型用) | 熱間打刻用刻印材として適しています |

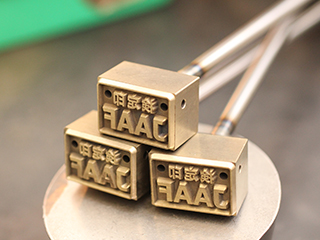

| その他の金属 | 黄銅(真鍮)、銅、ステンレス鋼、鋳鉄など | 焼印用、活字用、放電電極用、鋳型用などに使用されています |

*1 被打刻物(ワーク)の材質や打刻方法などの諸条件により異なります。

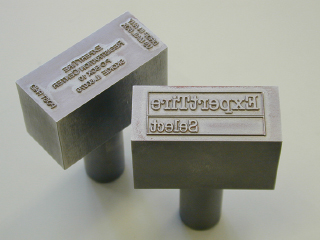

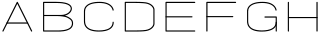

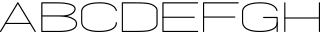

2.字体

被打刻物(ワーク)に打刻される字体の向きを御指定頂けます。

普通文字(右字)

打刻後に正読みする場合に適用します(通常刻印)

刻印側

被打刻側

型用逆文字(左字)

各種金型などに打刻し、文字などを反転浮出しさせる場合に適用します

刻印側

被打刻側

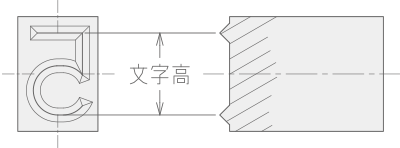

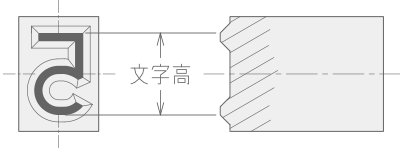

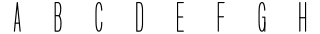

3.文字高

文字やロゴマークなどの大きさを指します。通常、尖った山の先端から先端までを指します。

またフラットフェイス(太み付)の場合、平面部端から端までを指します。

その為、彫刻寸法値と実際に打刻された文字の大きさに違いが生じますのでご注意下さい。

文字高0.5mm程度から彫刻可能です。

シャープフェイス(刃先)

フラットフェイス(太ミ付)

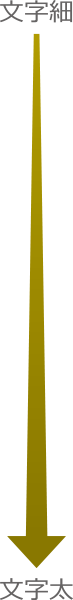

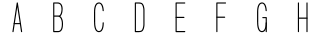

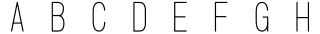

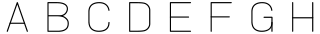

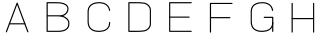

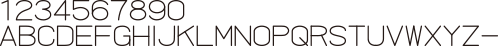

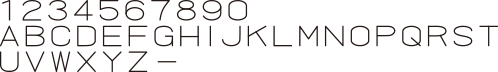

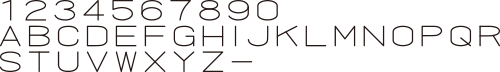

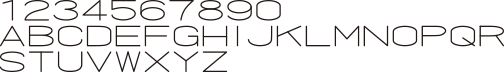

4.文字幅

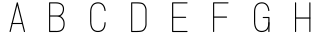

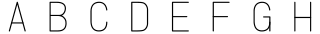

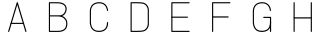

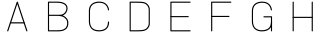

文字高に対し、比率で文字の横幅を設定することができます。

10:2~10:12まで13種類から御指定可能です。

| 縦横比率 | 10:2 |  |

|

|---|---|---|---|

| 10:3 |  |

||

| 10:4 |  |

||

| 10:5 |  |

||

| 10:5.5 |  |

||

| 10:6 (標準比) |

|

||

| 3:2 |  |

||

| 10:7 |  |

||

| 4:3 |  |

||

| 10:8 |  |

||

| 10:9 |  |

||

| 10:10 |  |

||

| 10:12 |  |

5.文字ピッチ

JAPANのような複数文字(連文字)の場合、文字ピッチを任意に指定することができます。

打刻エリアに合わせて文字ピッチや文字横幅を設定できますので、狭い打刻エリアや小さな刻印材でも彫刻が可能です。

-

ピッチ広い

-

ピッチ普通

-

ピッチ狭い

6.彫刻先端加工

彫刻文字の先端加工を変えることにより、打刻後のイメージを変えたり、被打刻物(ワーク)への金属疲労を軽減させたりすることが可能です。

打刻されるワークの特性やご使用方法に合わせて御指定頂けます。

シャープフェイス(刃先)

先端が尖った山のような状態です。標準仕様として一般的に幅広く使用されています。

刻印側

被打刻側

フラットフェイス(太ミ付)

先端に平らな面をつけた状態です。ロゴマークなどやホットスタンプなどの用途にご使用頂けます。

刻印側

被打刻側

ローストレス(先端R付)

先端にR付け加工を施し、被打刻物(ワーク)の疲労破壊や労力集中により生じる製品の割れなどを防ぎます。

主に、原子力や航空機部品、ガス関連資材などに使用されています。

刻印側

被打刻側

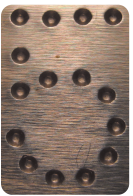

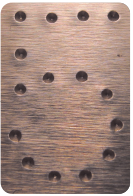

点文字

ローストレスと同様の使用目的を持ち、被打刻物(ワーク)への負荷を更に少なくする場合に有効です。

刻印側

被打刻側

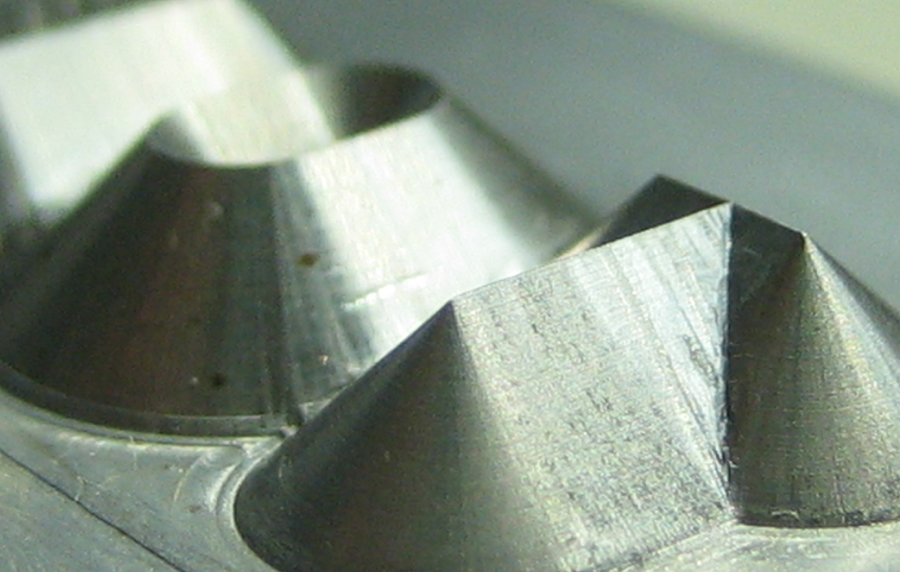

円錐文字

点文字より更に先端が尖った円錐形で加工され、皮革、厚紙、樹脂製品などに深めに打刻したい場合に有効です。

刻印側

被打刻側

二重文字(中抜文字)

ロゴマークなど輪郭だけを打刻したい場合や過大な打刻力(負荷)をかけずに打刻したい場合に有効です。

刻印側

打刻側

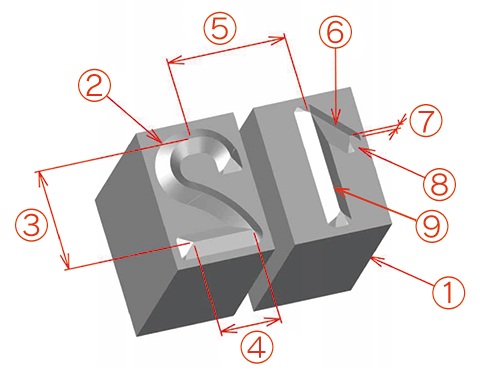

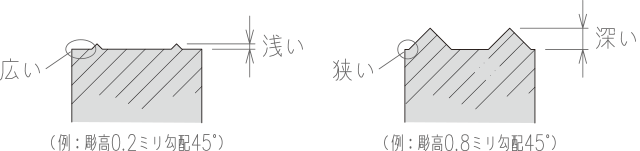

7.彫高

彫刻の彫り深さを指します。彫刻勾配や刻印材寸法により異なりますが、通常0.2mm程度から御指定可能です。

深く彫り過ぎると彫刻の裾野が広がる分、刻印材の幅や文字ピッチに制限が生じる場合があります。

8.彫刻勾配

彫刻の傾斜角度を指します。勾配角度を変えることにより、被打刻物(ワーク)に対して刻印の入りやすさを調整することができます。

彫高や刻印材寸法により異なりますが、通常勾配5°~勾配55°程度まで御指定可能です。

鋭角過ぎると刻印は入りやすくなりますが、その分欠け易さが生じます。

鈍角過ぎると欠け難くなりますが、その分刻印の入り難さが生じます。

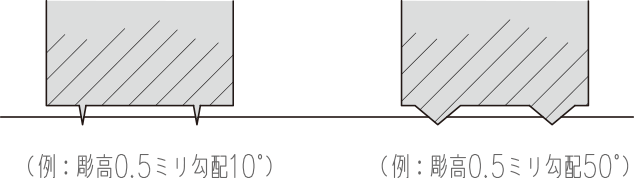

9.タガネ仕上げ

タガネという彫刻後の仕上げ工程を加えることにより、細部まで鮮明に写しだされる刻印を作り上げます。

弊社全ての刻印にタガネ処理を施しています。

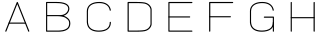

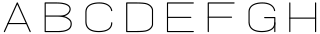

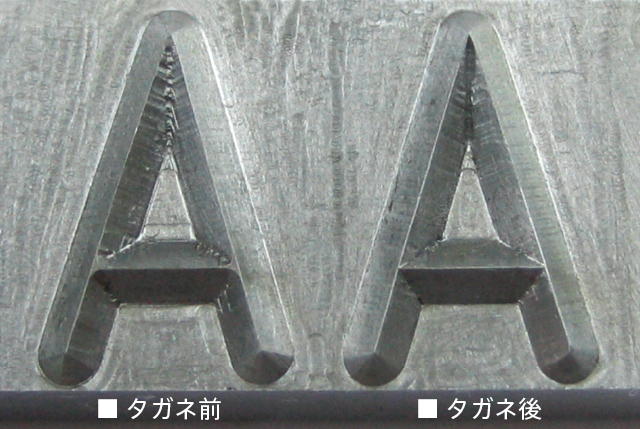

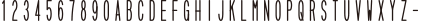

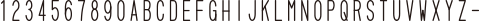

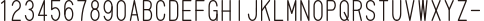

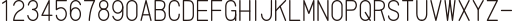

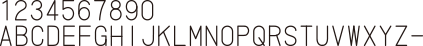

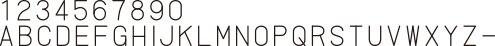

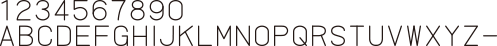

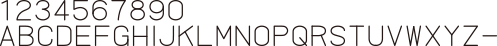

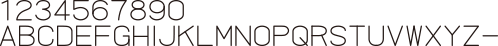

東京彫刻工業 字体表

| 縦横比率 | 字体 | |

|---|---|---|

| 準標準字体 | 10:2 |  |

| 10:3 |  |

|

| 10:4 |  |

|

| 10:5 |  |

|

| 10:5.5 |  |

|

| 標準字体 | 10:6 |  |

| 準標準字体 | 3:2 |  |

| 10:7 |  |

|

| 4:3 |  |

|

| 10:8 |  |

|

| 10:9 |  |

|

| 10:10 |  |

|

| 10:12 |  |

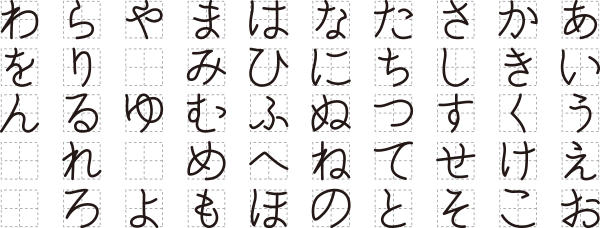

| ひらがな |

|---|

|

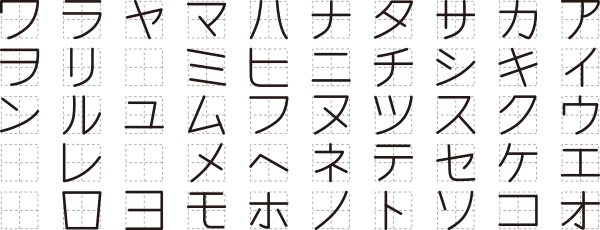

| カタカナ |

|

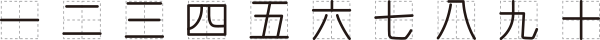

| 漢数字 |

|

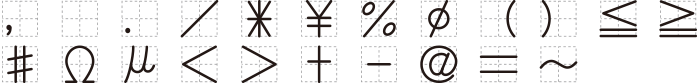

| 各種記号 |

|

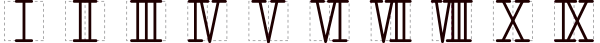

| ローマ数字 |

|

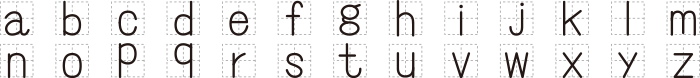

| 英小文字 |

|

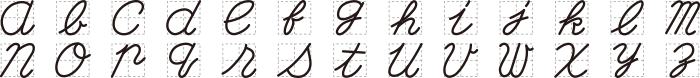

| イタリック(斜体) |

|

注)品質の向上にともない、予告なしに仕様が変更する場合があります。あらかじめご了承ください。

Japan - 日本語

Japan - 日本語